INQUIRY:

760-936-2797

AFTER-SALES:

760-936-2797

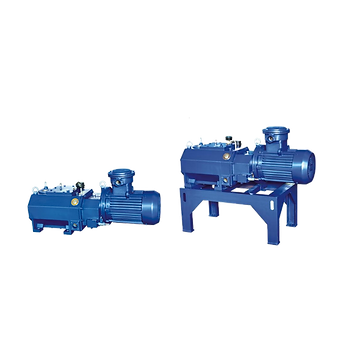

Compound Molecular Pump

TP Series

-

Oil-Free Clean Vacuum

-

High vacuum state

-

Lower noise

-

High pumping speed

Overview

Compound molecular pump is composed of a turbomolecular pump and a drag pump. It combines the characteristics of a turbomolecular pump with a high pumping speed and high compression ratio when handling molecular flow, and a drag pump with a high pumping speed and high compression ratio at high pressures. This extends the application range of molecular pumps.The compound molecular pump is non-selective and exhibits no memory effects on the pumped gas. Due to its high compression ratio for gases with large molecular weights, it can achieve clean high vacuum and ultra-high vacuum without the need for a cold trap and oil baffle.

Features

-

Oil-Free Clean Vacuum

-

Achieves very low back pressure, reaching a high vacuum state.

-

Higher pumping speed rapidly removes gases, accelerating the evacuation speed of the vacuum system.

-

With virtually no moving parts internally, it results in lower noise and vibration, leading to lower maintenance costs.

Typical Applications

Model | TP-200 | TP-600 | TP-1200 | TP-1600 |

|---|---|---|---|---|

Overall dimension(mm) | 208*152*266 | 265*236*457 | 294*267*467 | 327*296*467 |

Pump body baking temperature(℃) | < 80 | < 100 | < 120 | < 120 |

Oil filling volume(ml) | / | 100 | 100 | 100 |

Pump weight(Kg) | ≈ 11 | ≈ 30 | ≈ 34 | ≈ 39 |

Installation direction | Any angle | Vertical ±5° | Vertical ±5° | Vertical ±5° |

Water cooling cooling water flow

(L/min) | / | / | / | 1 |

Cooling water temperature(℃) | / | / | / | ≤ 25 |

Ambient temperature(℃) | / | ≤ 28 | ≤ 28 | / |

Cooling method | Air cooling | Air cooling | Air cooling | Water cooling |

It is recommended to use a

backing pump(L/S) | <2 | 4~8 | 8~15 | 15 |

Downtime(min) | <6 | <6 | <7 | <8.5 |

Start time(min) | <6 | <4 | <5 | <6 |

Vibration value(μm) | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 |

Use bearings | Imported ceramic bearings | Imported ceramic bearings | Imported ceramic bearings | Imported ceramic bearings |

Rated speed(rpm) | 30000 | 24000 | 24000 | 24000 |

Pumping rate(L/S) | 200 | 600 | 1200 | 1600 |

Front stage flange | KF25 | KF40 | KF40 | KF50 |

High vacuum flange | KF40 | KF40 | KF40 | KF40 |